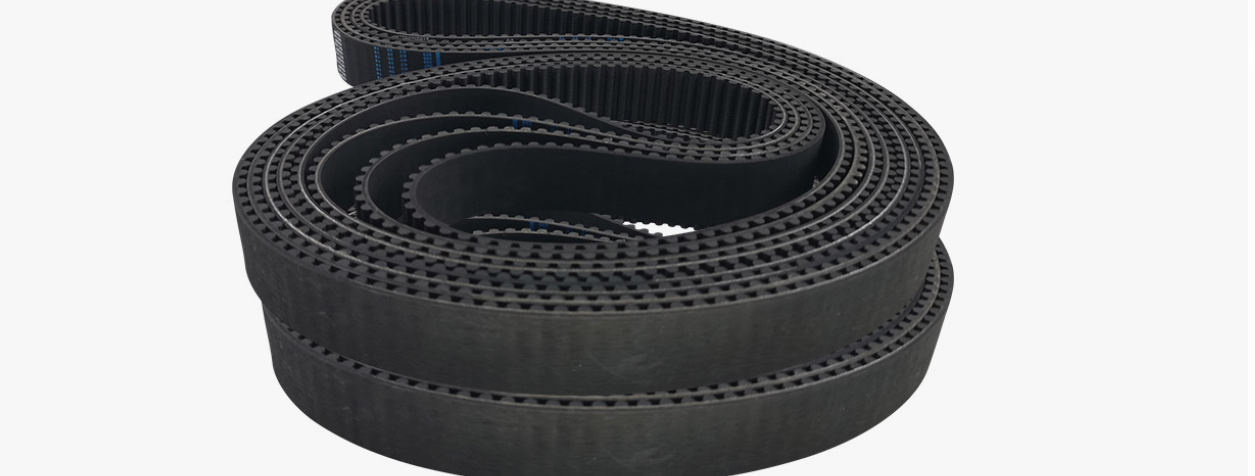

Double-sided rubber synchronous belts, as a highly efficient transmission tool, are widely used in various industries such as automation equipment, mechanical manufacturing, and transportation systems. Through precise tooth profiles and excellent material properties, they achieve efficient and stable power transmission. Compared to traditional belts or chain drives, double-sided rubber synchronous belts offer higher transmission efficiency, longer service life, and lower maintenance costs. However, users may encounter some common problems during use, affecting the performance and lifespan of the synchronous belt.

1. Common Problem: Synchronous Belt Slippage or Transmission Failure

Problem Description:

Synchronous belt slippage is a common fault, especially under high load or high-speed operating conditions. Slippage reduces transmission efficiency and can even affect the overall operational stability and accuracy of the equipment.

Possible Causes:

Insufficient tension: If the synchronous belt tension is too low, the belt teeth cannot fully engage with the gear teeth, leading to slippage.

Damaged gears or pulleys: Worn gears or mismatched tooth profiles can lead to poor contact between the synchronous belt and the gears, resulting in slippage.

Excessive load: Operating conditions exceeding the synchronous belt's design load can easily cause the belt surface to slip.

Improper lubrication: If there is oil or improper lubrication on the surface of the synchronous belt, it can also easily lead to slippage.

Solutions:

Adjust synchronous belt tension: Regularly check the tension of the synchronous belt and adjust it as needed to ensure a tight fit between the synchronous belt and the gears. A tension meter can be used to measure the belt tension and adjust it according to the manufacturer's recommended values.

Check gears and pulleys: Regularly inspect the tooth surfaces of the gears and pulleys to ensure there is no damage, wear, or unevenness. If gear damage is found, replace it promptly.

Avoid overloading: Ensure that the synchronous belt is not overloaded, set a reasonable load range, and avoid prolonged operation under overload conditions.

Cleaning and lubrication: Regularly clean the synchronous belt and pulleys to remove oil, dust, and other debris, and use suitable lubricants to maintain the synchronous belt in good working condition.

2. Common Problem: Premature Synchronous Belt Wear

Problem Description:

Premature wear of the synchronous belt shortens its service life and increases the frequency of replacement. Common wear phenomena include tooth surface wear and belt surface peeling.

Possible Causes:

Mismatched gears or pulleys: If the tooth profile of the gears or pulleys does not match the tooth profile of the synchronous belt, it will lead to uneven wear.

Excessively high operating temperature: High temperatures can cause rubber aging, accelerating synchronous belt wear, especially when working under high load or in high-temperature environments.

Unsuitable environmental factors: Dust, oil, and chemical substances in the environment can accelerate synchronous belt wear, especially in harsh industrial environments.

Frequent load shocks: Sudden load shocks or frequent starts and stops will accelerate synchronous belt wear.

Solutions:

Check the matching of gears and pulleys: Ensure that the tooth profile of the gears and synchronous belt match, and that the diameter, material, and other parameters of the pulleys meet the requirements of the synchronous belt. Use a suitable gear and pulley combination to reduce uneven wear.

Control operating temperature: Try to control the operating temperature of the synchronous belt to avoid the impact of high temperatures on the belt material. In high-temperature working environments, high-temperature resistant rubber synchronous belts can be used.

Maintain a clean environment: In harsh environments, regularly clean the synchronous belt and related components to prevent dust, oil, and other substances from entering the belt surface and reduce wear.

Avoid frequent load shocks: Design reasonable start and stop procedures to avoid frequent load shocks.

3. Common Problem: Synchronous Belt Breakage or Damage

Problem Description:

Synchronous belt breakage or damage will cause the entire system to malfunction and may even cause equipment damage. Synchronous belt breakage is usually caused by long-term overload, lack of maintenance, or material problems.

Possible Causes:

Overload: Working continuously beyond the rated load of the synchronous belt can easily lead to fatigue fracture of the belt body.

Uneven tension: If the tension of the synchronous belt is uneven, it may cause excessive stretching in some areas, leading to breakage.

Material quality problems: Low-quality rubber synchronous belts may have manufacturing defects, resulting in a shorter service life.

Excessive aging: The rubber material of the synchronous belt will age after long-term use, causing the belt body to become brittle, thus increasing the risk of breakage.

Solutions:

Reasonable Load: Avoid overloading the timing belt beyond its design limits. Regularly check the equipment's workload to ensure the timing belt operates within a reasonable range.

Even Tension Adjustment: Regularly check and adjust the timing belt tension to ensure uniform tension across the belt, avoiding excessive stretching.

Choose High-Quality Timing Belts: Select reliable timing belt brands to ensure the belt material meets the requirements and prevent premature breakage due to quality issues.

Regular Inspection and Replacement: Regularly inspect the timing belt's condition and promptly replace worn, aged, or damaged belts to prevent breakage accidents during operation.

4. Common Problem: Excessive Timing Belt Noise

Problem Description:

Timing belt noise is a common problem users encounter when operating equipment. Excessive noise not only affects the working environment but can also be a sign of equipment problems.

Possible Causes:

Excessive Tension: If the timing belt tension is too high, the contact between the belt teeth and the gears will be very tight, leading to increased noise.

Gear or Pulley Wear: Worn or uneven gear and pulley tooth surfaces can also lead to uneven meshing and generate noise.

Unsuitable Material or Design: Improper timing belt material selection or design may result in excessive noise during operation.

Solutions:

Adjust Tension Appropriately: Ensure the timing belt tension is moderate, not too tight. Excessive tension will cause the belt teeth to contact the gears too tightly, thus generating noise.

Check Gear and Pulley Wear: Regularly check the wear of the gears and pulleys, ensuring the tooth profile is intact, and replace them if necessary.

Choose Suitable Timing Belt Material: Select the appropriate timing belt material based on the working environment; some high-performance materials can effectively reduce noise.