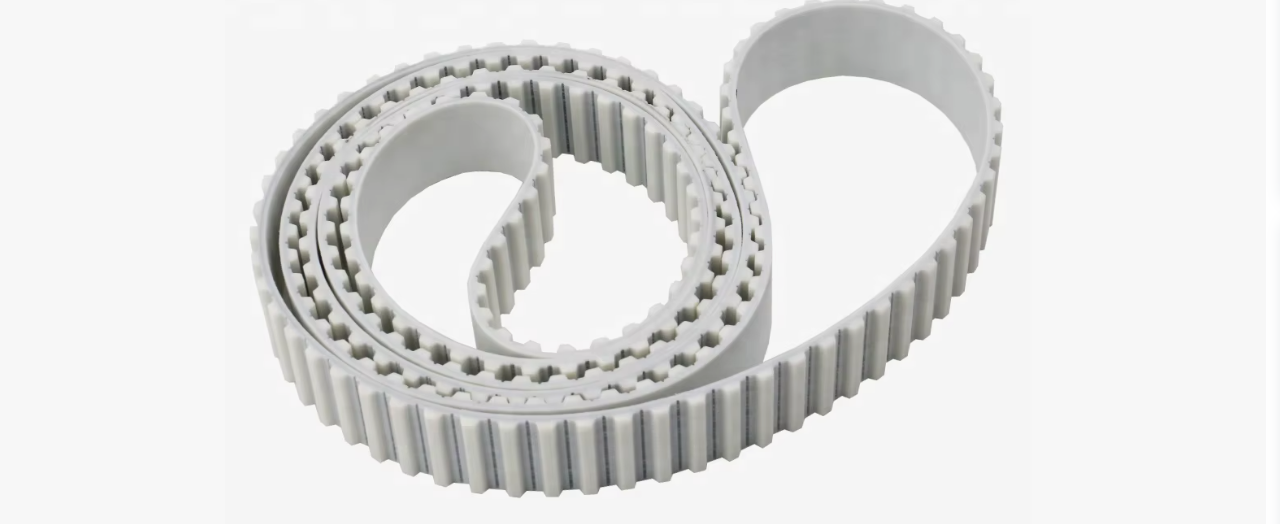

PU synchronous belts (polyurethane synchronous belts) are widely used in packaging machinery, automated equipment, conveyor lines, woodworking machinery, and precision positioning systems due to their high strength, wear resistance, and good oil resistance. However, during long-term operation or when the load fluctuates, the synchronous belt may slip, leading to decreased transmission efficiency, inaccurate positioning, or even machine shutdown. So, how should PU synchronous belts handle slippage? The following explains the causes and solutions.

1. Common Causes of PU Synchronous Belt Slippage

(1) Insufficient Tension

The synchronous belt needs a certain tension to properly mesh with the synchronous pulley. If the tension is too low, the belt will not be tight, the meshing will be loose, leading to tooth skipping and slippage.

(2) Wear and Aging of the Synchronous Belt

Although PU is wear-resistant, after long-term operation, the tooth profile may become shallower, the back belt may become shiny, and the tensile layer may fatigue. All of these will cause the synchronous belt to not mesh firmly with the pulley teeth.

(3) Wear or blockage of the timing pulley teeth

If the timing pulley teeth are blocked by dust, debris, or oil, the meshing force will decrease, which will also cause slippage.

(4) Overload or sudden impact

If the equipment load exceeds the bearing capacity of the timing belt, or if there are frequent start-stop or reverse impacts, the timing belt will slip momentarily.

(5) Installation deviation or non-parallel pulleys

If the timing belt pulleys are not on the same plane, or the tensioner is not in the correct position, the timing belt is prone to misalignment and poor meshing, resulting in slippage.

(6) Oil or moisture on the surface

Oil, water, or dust adhering to the surface of the timing belt will reduce friction, making the timing belt more prone to slippage.

2. Solutions for PU Synchronous Belt Slippage

(1) Adjusting the Synchronous Belt Tension (Most Common Solution)

If slippage is caused by insufficient tension, simply readjust the tensioning mechanism to restore the synchronous belt to the appropriate tightness.

Experience-based judgment: Gently press the center of the synchronous belt by hand; an offset of approximately 2%–3% of the center distance is suitable.

(2) Replacing the Worn Synchronous Belt

When wear, cracks, hardening, or significant loss of elasticity are observed, the belt should be replaced promptly. Severely worn synchronous belts cannot completely resolve slippage regardless of tension adjustments.

(3) Cleaning or Replacing the Synchronous Pulley

If powder accumulates in the grooves of the synchronous pulley, it should be cleaned. If the grooves are worn or sharpened, the synchronous pulley must be replaced; otherwise, the synchronous belt will be damaged again more quickly.

(4) Reduce load or select a higher grade synchronous belt

If the equipment load is too high, the following should be done:

Reduce instantaneous impact force

Adjust the process cycle time appropriately

Replace with a wider or higher load-bearing capacity PU synchronous belt

3. Effective methods to prevent synchronous belt slippage

To avoid repeated slippage of the synchronous belt, the following measures can be taken:

Regularly check the synchronous belt tension

Clean the synchronous pulleys every 1-3 months

Avoid overloading

In dusty environments, install protective covers

Replace the synchronous belt when its service life expires

Avoid frequent start-stops or strong impacts on the equipment

PU synchronous belt slippage is mainly caused by insufficient tension, wear, synchronous pulley failure, installation misalignment, and excessive load. By adjusting the tension, cleaning or replacing the synchronous pulleys, calibrating the installation, and controlling the load, the equipment can be quickly restored to normal operation. Proper maintenance in advance can further prevent premature damage to the synchronous belt and improve the efficiency and reliability of the equipment.