-

How to Choose the Right Coated Rubber Belt for High-Speed Automated Packaging: A Complete Guide to Durability and Precision

The Critical Role of Coated Rubber Belts in Modern Automation In the fast-paced world of automated packaging and cable manufacturing, the reliability of a transmission system often hinges on a single...

View More -

How Long Does a Rubber Timing Belt Last? The Ultimate Guide to Lifespan and Maintenance

For engineers, mechanics, and vehicle owners alike, the question "How long does a rubber timing belt last?" is more than just a maintenance query—it is a critical safety concern. A rubber timing belt...

View More -

Which Is Better, V Belt or Flat Belt? A Comprehensive Comparison for Industrial Efficiency

In the world of mechanical power transmission, the debate over Which is better, V belt or flat belt? has persisted for decades. Choosing the right drive belt is not just a matter of preference; it di...

View More -

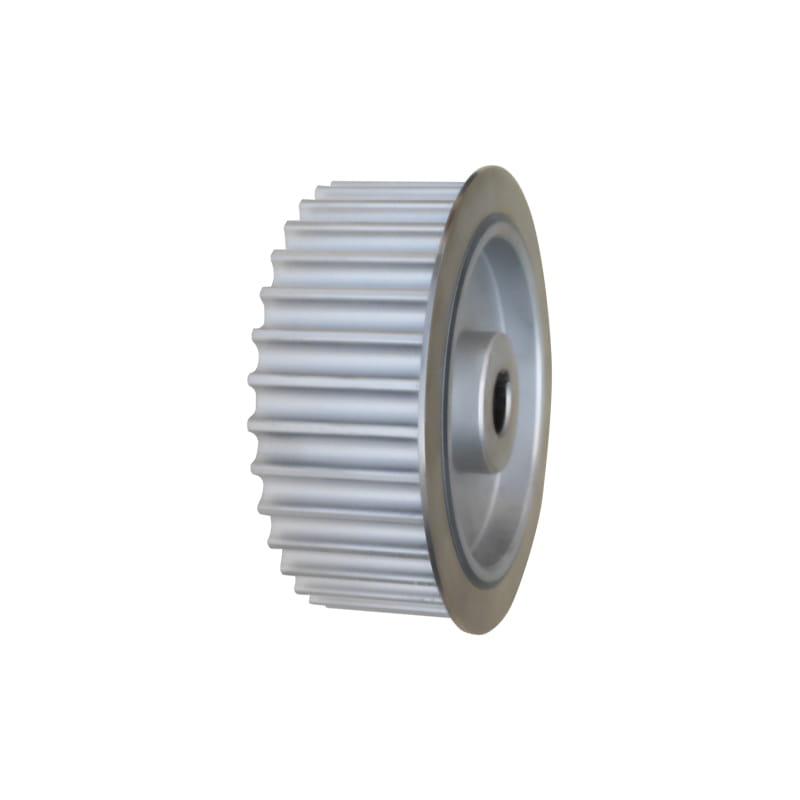

The Ultimate Guide to Selecting a Synchronous Pulley: Enhancing Driven System Efficiency

In the world of mechanical power transmission, the efficiency of a driven device system hinges on the precision of its components. Among these, the synchronous pulley stands as a critical element. De...

View More -

How to Optimize Flour Mill Efficiency with Toothed And Ribbed Belt: The Ultimate Guide

In the demanding environment of industrial milling, the reliability of power transmission is not just a preference—it is a necessity. Many factory managers and engineers often ask, "How can we achiev...

View More -

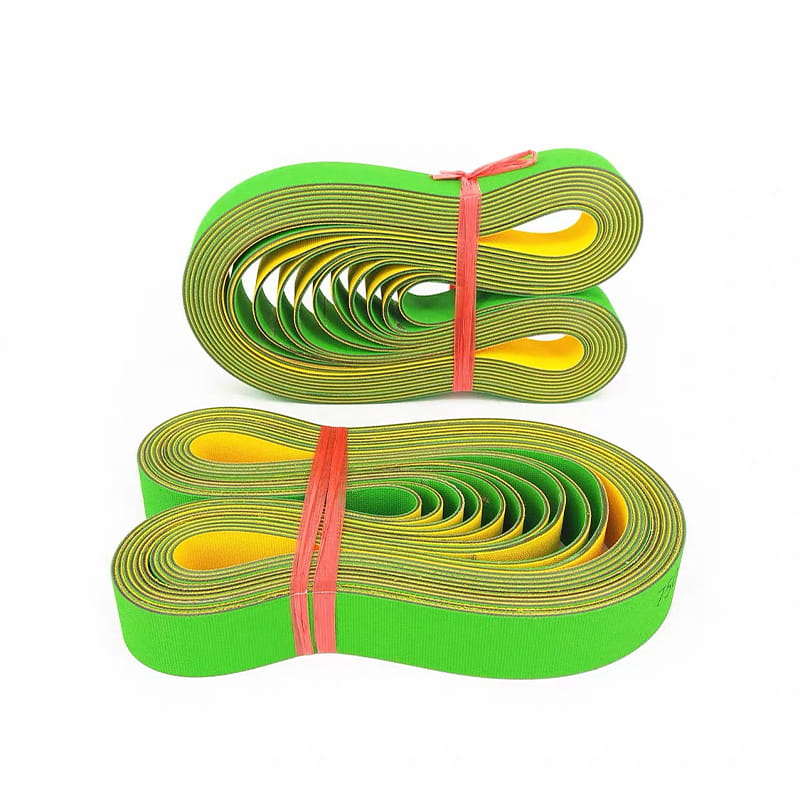

The Rise of High-Performance Endless Rubber Flat Belts in Modern Manufacturing

In the rapidly evolving world of industrial automation, the demand for components that combine speed, durability, and precision has never been higher. Manufacturers are moving away from traditional l...

View More